GRAYSHA AUDREN

Interviewed by Hashika & Nicole

May 16, 2020

As a designer, you have the power to invoke change. Sustainability is a design problem and inefficiency to be solved through creative re-design. As a graduate of Central Saint Martins Textile Design , it became evident that textile production is interwoven with politics, economics, trade, society and governments. Outdated manufacturing models and business structures no longer serve us and it is time for a major rethink. The best way to change the entire system is to start at the beginning; the making of the cloth.

There is little to no conversation happening between textile creatives, technologists and engineers. Innovation can only occur when interdisciplinary ideas cross-fertilize. By choosing to specialize in woven textiles, I want to bridge the gap between technical innovation and creative design for more holistic solutions.

I strive to create textiles that tell a story, that propose new sustainable solutions, with close attention to technological advancement, and the value of the hand craft in our future thinking. As a problem solver with an array of experience in the industry, I have a modern understanding of the fashion system from trend, to woven fabric, to garment prototype, to fittings, to the catwalk, to production, to customer, to waste.

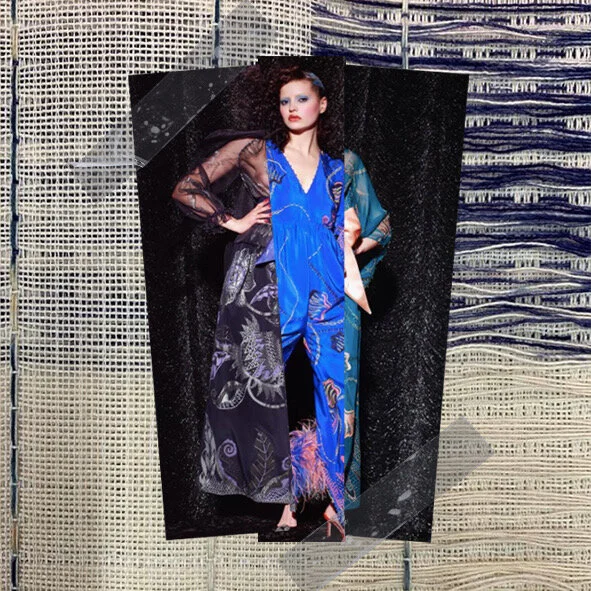

The fashion industry has been a part of my life since, gosh I don’t even know how long, forever? I was scouted when I was 13 and my mother is in the business as well so I have always been involved in it. My body was a canvas for other people to manipulate and express their ideas through and I think being able to separate my self and my emotions from my body was incredibly helpful for me. however the more and more I took part in prints or editorials or runway opportunities, I realized more and more that my body was a business, and I realized I wanted to be part of the larger discussion in enacting change. designers have the power to design for change, to invoke change.

As a human being I have always been instinctively curious. for example, even though I studied fashion at university, I’ve been extremely interested in government infrastructure and its impact on the working world. one of the main dynamics that I didn’t really understand but wanted to figure out is why elements such as sustainability, efficiency and cost effectiveness are in competition with each other especially in the fashion industry. I wanted to understand how they all are linked.

Graysha: People will buy things that are pretty. It’s an art form right? The fashion industry at the end of the day is to make products and sell them and so as a creative and a consumer, I think that you have to be aware of that and what leads to that if that is exploitation and endless consumerism. I think that rebranding of the fashion industry needs to happen. They market it as this escapist’s dream, that it’s art. I mean, even the art world is exploitative. being aware of that is really important.

Nicole: So where did you start with your research?

Graysha: One of the main dynamics that I didn’t really understand but wanted to figure out is why elements such as sustainability, efficiency and cost effectiveness are in competition with each other. I really delved into rethinking systems and having a holistic system idea rather than piecemealing it. One of the biggest books that really inspired me was William McDonough’s Cradle to Cradle. A cradle to cradle approach is a new design thinking approach where you are creating a regenerative system so that waste is actually a resource to create the next product. There is a circular loop of materials and resources.

I think it’s tricky with big fashion houses because they have long standing relationships with their manufacturers and long standing production processes.

Hashika: Have you seen any fashion brands take part in these initiatives? In regards to the cradle to cradle approach, I’m also curious that when there’s so much high constant demand for fashion, how do you introduce those systems? How do you meet that demand in a sustainable way?

Graysha: Firstly, I think it’s tricky with big fashion houses because they have long standing relationships with their manufacturers and long standing production processes. They have shareholders and incentives towards making money. I think real change is going to be difficult for those people which is why its exciting and inspiring to see smaller companies and individuals because they have that freedom and they don’t have those obligations so they can completely rethink systems. A cradle to cradle approach is just looking at systems holistically and taking everything to account. To do that, that requires an almost complete paradigm shift. That’s going to take a really long time. I think anyone that’s working towards circularity is doing the right thing. Transparency and figuring out who in your supply chain is doing what and where do things come from.

You’re seeing that a lot of companies are doing that. Supima Cotton has a DNA sequencing technology to figure out where your cotton was and if its actually organic. So, if we make our supply chains more transparent, innovators and scientists will be able to see that and figure out where the problems are. With our insatiable consumerism, it’s problematic. Even if you were to have a completely circular value chain, every product uses resources and energy right? So, I think a big push that we are seeing but needs to be more ingrained in us, is to slow down consumerism. This is one of the exciting things in our current pandemic because you’re seeing people slow down. You see this kind of breath and reevaluation of our values and what’s important to us. The slowing down of consumerism. I hope that that carries through because that buys us more time and also again its a paradigm shift.

There’s this great research journal - Ellen MacArthur Foundation. They’re this great research initiative and they talk about how little wear each garment has. It has 7 to 10 wears before it goes to landfill. That needs to change. So, sustainability being that trend, you’re seeing a lot of people being aware of it and working towards it. You’re seeing a big consumer push for companies to be more responsible. I hope that trend stays. I think progress is being made slowly.

I’ve basically created a way of weaving an entire garment at once so you are shortening supply chains and you’re designing out fabric wastes and offcuts.

Nicole: So, with your own company, Blood Sweat & Textiles, what are you looking toward to do with that? What is your mission? Tell us the story. What inspired you?

Graysha: The main project that I have been working on is the Seamless 3D Woven garments. That was my graduate project but also my current project now. I’m a year in and trying to find funding, working on the research and development stages of that. To explain that project, essentially, it’s using 3D weaving technology and lending itself to automated garment manufacturing processes to work towards a circular supply chain and a circular fashion industry in general. So what that means in simpler terms is I’ve basically created a way of weaving an entire garment at once so you are shortening supply chains and you’re designing out fabric wastes and offcuts. You’ve got a rectangular piece of fabric and you put your pattern pieces on top of it and you cut around. Those are offcuts, waste. So, there are a lot of steps and transport in supply chains. The fibre is made, let’s say in India and transported to Indonesia. Then it’s sewn and then transported somewhere else and it finally goes to the consumer. When you shorten that supply chain, essentially automating it, creating an entire garment at once, you are drastically reducing energy usage and lending itself to a localized production system. That’s the project I’ve been working on and kind of where my company is forming. That’s going to be what I’ll be doing for a while.

It’s going to take a long while because currently it’s still very much in the research and development phase. You’re weaving 6 layers at a time. I kind of associate weaving a bit like coding so I’m kind of creating a new code and then I force machines to take my mind. So there’s a lot of trial and error with that.

Nicole: The technology is already there. It’s figuring out how to get it to work right?

Graysha: That’s a big thing as well. Especially, with this project, I wanted to tie in manufacturing efficiency, cost effectiveness and applicability. If you’re able to use looms that are already in existence, you’re able to sell that idea much more easily than something that’s ten years out.

Hashika: I know a lot of big fashion houses are outsourcing their labor and having a lot of garment factories established in third world countries where there’s cheap labor, tons of energy usage and unsustainable methods of manufacturing. What do you see happening to these factories in the future? Do you think companies will come up with more sustainable ways to create garments in these places or do you see a lot of companies shifting to localized production?

Graysha: Garments travel a long distance in our current system. I read somewhere that the fashion industry emits more CO2 than all flights and maritime shipping combined so it’s a lot. This is kind of where this project is going as well. Automation is going to be a big solution to a lot of our problems because what’s going to happen is that it’s a lot cheaper to have a machine than have all of this labor. I think automation is going to see a localized production system. I’m hesitant to say it’s going to move from third world to first world. I think every big consumer base is going to have its own localized production. You’re seeing third world rising to middle class consumers in terms of usage.

I think what’s happening currently in this pandemic and what I hope will carry through is that we will start to realize this “lower-skilled” labor is going to be seen as more important and valuable. People will see human lives as something that should be protected, not exploited. With this current pandemic, you’re realizing that essential workers are the foundation of our economy and the key to our survival. So I think the systems that condone the exploitation of human labor needs to change. One of the ways that you do that and what my project talks about as well is that people talk about how automation will leave a lot of people out of work because instead of the human being the machine, the human just oversees it. You can work around that by having a retraining program. Bill Gates came up with something when AI and automation gets rid of a lot of jobs, you introduce retraining programs to humans so that instead of sitting at sewing machines sewing lines, they’re moving around and making sure everything is functioning.

The human element, with any type of automation, is never going to design itself out completely. There’s always going to have to be human intervention. Maybe drastically less but still very much there. Localized production is a huge thing. Automation will help with that just because in America and Europe there is a lack of space. You can’t have massive Bangladeshi garment factories right? You’re going to have to condense that. Automation helps with that.”

I’m seeing a lot of people taking the time during this quarantine to reevaluate, reassess and see what’s important. I think that’s been a really big part of what I’ve been doing. I’ve been going nonstop since I graduated and now I have time to rethink what’s important and research.

I think it’s time to absorb knowledge and plan a strategy for when we get out. Embrace the change of pace and embrace the slowing down. I don’t think we ever get that opportunity ever. It’s very tragic what’s happening but it’s also an opportunity to just slow down. I’m trying to meet the situation with optimism. I read an article the other day where this guy is going back to history.

At every big catastrophe, there’s always been on the other side an influx of innovation and growth and the ability for people to paradigm shift in a matter of months. It’s been two months since everything hit America and since then so much has happened. We’ve seen a global effort to work at one cause and I’ve never seen that. You’ve always had competing ideas. Seeing the entire world come together to fight one day and that’s special. I hope that after this is over, we don’t stop doing that. In the short term, there’s a virus but in the long term, there’s the end of humanity and that needs to stay in our minds.

What’s really exciting is that you’re seeing the slowing down of consumerism. I’ve said that before but people are realizing what they don’t need. You have those people that are Amazon addicted but that’s drastically decreased. We’ve seen people “make do and mend” like in the Second World War.

In human psychology, we go from problem to problem. It’s a systematic thing. When there’s long term abstract problems, they are put on the back bender. We see global warming becoming less and less abstract. We’re seeing wildfires in Australia and stuff like that. It’s something that is relatively soon.

What I really hate is the responsibility consumers have to change. I think it’s important for consumers to be aware because money is power so shop wisely and correctly. But I don’t think the responsibility should be on the consumer’s side because they are proportionally a very small percentage of the actual problem.

The real problem is big business corporations and governments and those need to change with regulations. We need corporate responsibility.